Such a high failure rate is very unusual and unacceptable for engineered structures! What is the reason for such high failure rate for MSE walls in particular and retaining walls in general? Based on published studies and Geo-Technology Associates, Inc.’s own experience during more than 30 years of practice, the contracting methods for both design and construction of walls are a big contributing factor to the high failure rate of the walls.

Lack of attention to details/setbacks during site layout and grading and procurement practices that push the design responsibilities to the wall contractor are significant contributing factors. The wall contractors frequently utilize high-volume, low-cost, out-of-town (frequently out-of-state), small engineering firms that operate more as “wall design factories” with limited manpower and expertise. The cutthroat competition for the work leads to incorrect and/or optimistic assumptions in the design. Therefore, some of the critical design issues (e.g., global stability of the wall, site-specific soil conditions, and available backfill materials) are not addressed properly or left for others to address. Use of low-quality backfill, inadequate quality control/testing during construction, and locating utilities or temporary/permanent stormwater management (SWM) facilities too close to the wall, further increases the potential for problems or failure of the walls.

We recommend the following dos and don’ts to reduce the risk of problems and failures of retaining walls:

- Do not be penny wise and pound foolish! Allocate and invest adequate budget for the design and construction of walls that will last for the useful life of the development.

- The civil engineer should account for the wall thickness; face batter; minimum setbacks for railing and guardrails; and setbacks from curbs, utilities, and SWM structures during the site layout and grading.

- Retain a local and experienced geotechnical engineer to perform borings and design the retaining wall. The project geotechnical engineer is generally in the best position to design walls for the site.

- Use design-bid-build process for construction of the wall. Retain a local and experienced contractor to build the wall.

- The wall designer should take into account the site-specific soil and groundwater conditions, planned utilities, and other facilities in the vicinity of the wall. The designer should perform global stability analysis of the wall using site-specific and meaningful soil parameters.

- Retain the project geotechnical engineer/wall designer to provide full-time observation and testing services during construction.

- Assess and incorporate measures to improve surface and subsurface drainage in the vicinity of the wall.

- Use nonclayey, sandy soils for wall backfill. Well-graded soils form better backfill and improve drainage. Avoid beach sands (poorly graded sands classified as SP per the Unified Soil Classification System) as wall backfill. Beach sands are prone to washouts and resulting settlement and failures.

- Use open-graded backfill for the portions of the walls subjected to permanent or periodic flooding (e.g., walls adjacent to or within SWM ponds).

- Avoid temporary sediment traps or concentrated water discharge in the vicinity of the walls.

- Stabilize the areas near the top and bottom of the wall immediately after wall construction.

- Inspect and maintain the wall drainage system and ground around the wall on a regular basis.

Happy walling!

Ravi Malviya is a Vice President GTA with more than 25 years of geotechnical and site engineering consulting experience throughout the mid-Atlantic and New England.

Ravi Malviya is a Vice President GTA with more than 25 years of geotechnical and site engineering consulting experience throughout the mid-Atlantic and New England.

Concentrated discharge resulted in sinkhole and undermining of wall foundation.

This 25’+ high wall failed within months of construction. It was reconstructed and failed a second time. Why? Inadequate global stability assessment due to designer’s lack of understanding of site soils.

Lack of stabilization and uncontrolled runoff above the wall resulted in washout of wall and foundation soils.

Undermining of foundation support soils resulted in failure of the wall.

Slides of the Marlboro Clay (reddish-brown in color, bottom of picture) layer after a storm event, during a mass excavation and replacement slope stabilization.

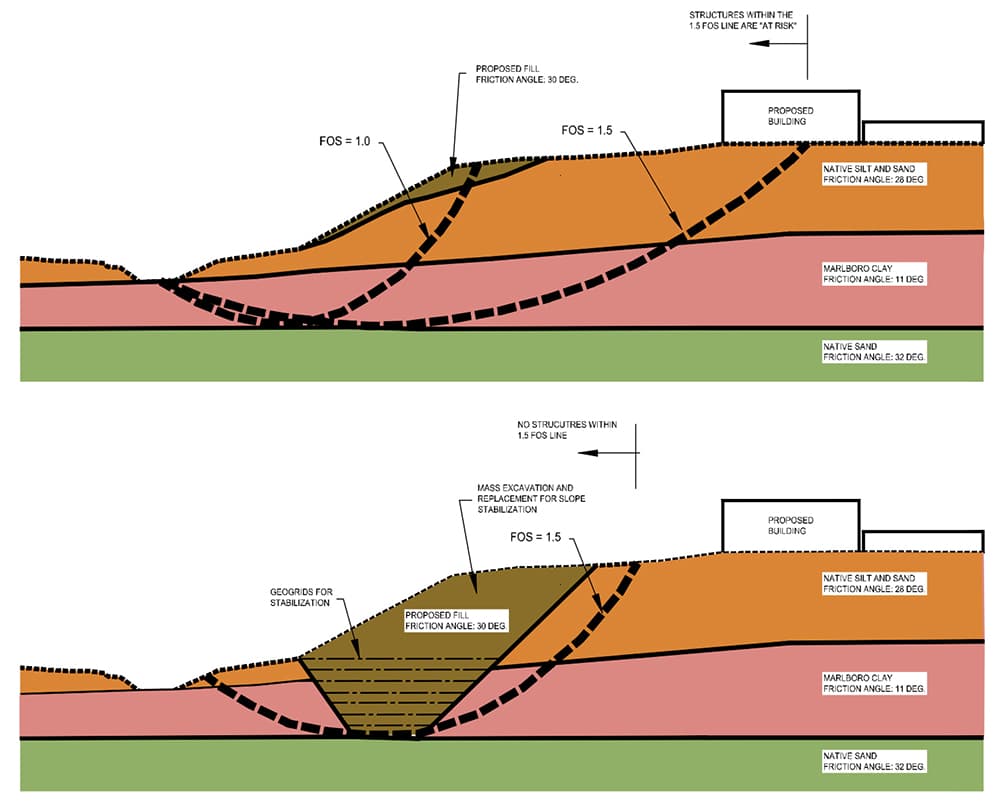

Slides of the Marlboro Clay (reddish-brown in color, bottom of picture) layer after a storm event, during a mass excavation and replacement slope stabilization. The top diagram identifies slope instability due to the presence of Marlboro Clay. The planned structures are impacted by the 1.5 FOS line. The bottom figure shows a mass removal and replacement to stabilize the slope. This is very expensive, and can possibly be avoided with proper analysis and input from the geotechnical engineer prior to permitting and final site designs.

The top diagram identifies slope instability due to the presence of Marlboro Clay. The planned structures are impacted by the 1.5 FOS line. The bottom figure shows a mass removal and replacement to stabilize the slope. This is very expensive, and can possibly be avoided with proper analysis and input from the geotechnical engineer prior to permitting and final site designs.

Richard Lake is an Associate with GTA, and a New Jersey Licensed Site Remediation Professional (LSRP). Rich has more than 20 years of experience providing environmental consulting for sites throughout New Jersey and Pennsylvania.

Richard Lake is an Associate with GTA, and a New Jersey Licensed Site Remediation Professional (LSRP). Rich has more than 20 years of experience providing environmental consulting for sites throughout New Jersey and Pennsylvania.

Ben Dinsmore, P.E., is an Associate with GTA and has 19 years of geotechnical and site engineering consulting services, primarily in the Baltimore – Washington, D.C. corridor.

Ben Dinsmore, P.E., is an Associate with GTA and has 19 years of geotechnical and site engineering consulting services, primarily in the Baltimore – Washington, D.C. corridor.

There are steps that you can take to prevent this scenario from happening to you. These steps start before the concrete is ordered, continue the day of placement and include the days and weeks following placement.

There are steps that you can take to prevent this scenario from happening to you. These steps start before the concrete is ordered, continue the day of placement and include the days and weeks following placement. Water cement ratios and admixtures matter. A water to cement ratio, weight of water divided by weight of cementitious material in a mix, of 0.45 is recommended. Higher water to cement ratios, more water, result in less durable concrete. Air entrained concrete is a must for exterior concrete or concrete that will be exposed to freeze-thaw cycles during construction. Air entraining admixtures create small regularly sized and spaced air bubble in the mix. The air bubbles in the concrete allow a place for water and ice crystals during freezing and thawing. If air entrainment is lacking, internal pressure in the concrete builds and the durability of the concrete will be a problem.

Water cement ratios and admixtures matter. A water to cement ratio, weight of water divided by weight of cementitious material in a mix, of 0.45 is recommended. Higher water to cement ratios, more water, result in less durable concrete. Air entrained concrete is a must for exterior concrete or concrete that will be exposed to freeze-thaw cycles during construction. Air entraining admixtures create small regularly sized and spaced air bubble in the mix. The air bubbles in the concrete allow a place for water and ice crystals during freezing and thawing. If air entrainment is lacking, internal pressure in the concrete builds and the durability of the concrete will be a problem. Scott J. Taylor, P.E. is an Associate with GTA and has more than 20 years of geotechnical and materials testing experience in the Baltimore – Washington, DC corridor.

Scott J. Taylor, P.E. is an Associate with GTA and has more than 20 years of geotechnical and materials testing experience in the Baltimore – Washington, DC corridor.